Rusting (O-Level chemistry)

For revision questions and answers download PDF below: rewrite the notes to possess them

RUSTING OF IRON

When iron is left in damp air for some time it become covered with a brown coat called rust. Chemically rust is hydrated iron III oxide Fe2O3.xH2O.

Disadvantage of rusting

- Weaken objects made of iron

- Makes objects made of iron look ugly

Conditions necessary for rusting

- Oxygen not air

- Water

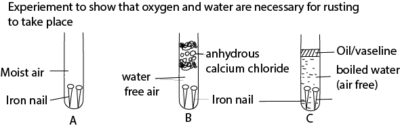

Experiment to show that oxygen and water is necessary for rusting

The experiment is set up as shown above and left for several days

- Test tube A contains nails and moist air

- Test tube B contains nails and dry air because moisture is removed by anhydrous calcium chloride

- Test tube C contains nail and air free water; boiling removes dissolved air from water while a layer of oil prevents entry of air into water

Observation after several days

- In test tube A rusting took place because there is both oxygen and water necessary for rusting to take place.

- In test tube B rusting did not take place because there was not water

- In test tube C rusting did not take place due to absence of air

Conclusion

Both oxygen and water are necessary for rusting to take place

Method of preventing rusting

- Keeping iron and steel equipment in air or water free environment, i.e., in the dry places (from water).

- Oiling (protects equipment from water and oxygen).

- Painting (protects from both air and water)

- Tin plating protects iron from both air and water; however, tin-plate is only effective provided the layer of tin remains intact

- Galvanizing: this is coating iron with zinc. Zinc protects iron because it is passive in air but also it can reduce iron III to ion.

For revision questions and answers download PDF

Sponsored by The Science Foundation College =256 753 80 27 09

Compiled by Dr. Bbosa Science

CATEGORIES O-level chemistry

TAGS Dr. Bbosa Science

Like it

Your writing is top-notch. Garden & Outdoor

You have a real knack for this topic. Indian Cricket

Join the best colleges easily with MBBS Direct Admission in Chhattisgarh.

Test your skills and luck with the immersive Raja Luck Game.

Discover key aspects of Raja Luck for better planning.

Dive into the world of Goa Games and test your strategy skills in a vibrant, immersive environment.

Share your unique Invitation Code to invite others and earn referral bonuses through TS EARN.

Don’t miss out on special promotions; use the Raja Games Invite Code today.

Boost your video gaming experience with special offers from the Diu Win Invite Code.

Improve functional effectiveness with safe and high-end Server Rental in Hyderabad.

Win real rewards and enjoy a thrilling experience with 55 club.

Carry out structured Technical Roadmap Planning to improve product advancement and IT effectiveness.

Avoid purchaser’s remorse with Smart Shopping Guides that aid you select wisely.

With Onlymp3 Converter, I no longer struggle with complicated software for transforming my favorite songs.

This detailed short article is an excellent resource! Tourists should understand Escort Service In Nainital can provide friendship during their go to too.

Using Himalayan Spices offers the food an unique and aromatic touch.