Measurements, Machines, tools and farm structures in agriculture

The factors that may affect the level of farmer’s investment in a farm

- Capital

- Size of the farm

- Nature of enterprise

- Security

- technology

Measurements on a farm

- Measurement of length, area and volume

- Short distance: are measured by using micrometer screw guage (mm) and Varvier calpers in cm.

- Long ditances: are measured by ruler or tape measure in meters (m)

- Area: is measured in mm2, cm2, m2, km2 and hectares.

- Volume is measured in cm3/ml, litres, , m3 and mm3. (1l = 1dm3 = 1000cm3). Volume is measured by measuring cylinder, burrette, pipette, syringe.

Measurement of mass

Mass is measured by weighing balance in grams (g) and kilogram (kg)

Measurement of time

Time is measured by a watch and stop clock in seconds (s), minutes (mins) and hours. 1hr = 60minutes = 60 seconds.

Density (ρ)

Density is mass over volume. Units g/cm3 or kg/m3.

Force

It a push or pull on an object. It changes a body’s state or rest or motion.

Types of forces

- Elastic force is force possessed by a stretched/compressed material e.g. rubber band and spring.

- Tension force is a force acting towards its support

- Centripetal force is force that keeps an object moving in a circle

- Gravitation force is the force of attraction towards the earth

- Mmagnetic force is a force of attraction between magnets or a magnet and a magnetic material.

- Electrostatic force is a force between charged particles

- Weight is the force of gravity acting on a body.

- Cohesion force is a force of attraction between molecules of the same kind e.g. between a molecule of water and another molecule of water.

- Adhesion force is a force of attraction between molecules of the different kind e.g. between a molecule of water and a molecule of glass

- Friction force is a force that resists motion.

Some uses of friction

- Allow people to walk and tyres to grip the surface of the road during movement

- Allow vehicles to brake

- Allow grip of objects

- Enable a matchstick to start fire

Disadvantage of friction

- Reduces efficiency of a machine

- Causes unnecessary noise

- Cause unnecessary heat

- Cause wear and tear of objects

Ways of reducing friction

- Lubricating surfaces

- Use of ball bearings between surfaces

- Polishing surfaces

- Use of rollers between surfaces

- Streamline of objects such as boats and aeroplane

Ways of increasing friction

- Making surface rough

- Drying surfaces i.e. removing lubricants

Simple farm machines

A machine is a device that makes work easier.

In machines an effort (force in neuton) is applied to move the load.

The qualities of a simple machine used on a farm

- easy to use with minimum fatigue.

- Light to transport

- Easily available i.e. made of local material

- Durable

- Easy to maintain

- Cause no injuries to animals and man

Effort of a simple machine

The effort can be

Muscular effort from man or

Force derived from an engine.

Principle of simple machines

The principle used in a simple machine is to produce a bi force overall, small distance by using a small force over large distance.

The force which we apply to the machine is know as effort E and the load we have to overcome is is known as the load (L), both force and load are measured in neutons.

Simple machines

These are devices that work with one movement and change the size and direction of force.

Examples of simple machnes include levers, pulley, hydraulic, gears, screws, and inclined planes

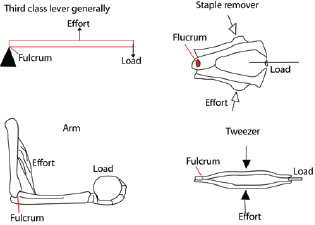

Levers

A lever is a rigid bar which is free to move about a fixed point, the Fulcrum or povot

Levers are divided into three classes

- The first-class levers

- The second-class lever and,

- Third class levers

First class lever

This is a type of lever in which the fulcrum is between the effort and the load.

Examples of first-class lever include Craw bar, scissor, beam balance, scissor and pair of pliers,

Second class lever

Here the load is between the effort and fulcrum.

Examples are wheelbarrow, nutcracker and office punch

Third class lever

Here the effort is between the load and fulcrum.

Examples are wheelbarrow, nutcracker and office punch

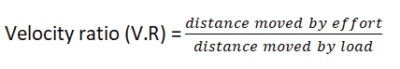

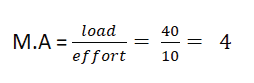

Mechanical advantage (M.A)

This is the ratio between the load and the effort applied. i.e.

Significance of mechanical advantage

The bigger the mechanical advantage the better the machine since small effort can lift a bigger load.

Factors that may lower mechanical advantage

Friction; the higher the friction the lower the mechanical advantage

Weight of moving parts: the heavier the parts the lower the mechanical advantage

Significance of velocity ratio

The bigger the velocity ratio the less effort required to do work and the more efficient the machine. Or the machines requires less effort to overcome a big load when effort moves a bigger distance compared to the load in a uinit time.

Example 1

A load of 100N is raised through 6m when an effort of 40N moves through 24m.

Calculate

(i) mechanical advantage

(ii) velocity ratio

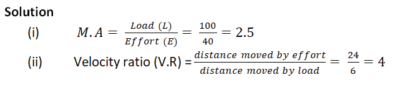

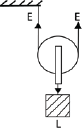

Pulleys

A pulley is a wheel with a groove ring which passes or string .

- The effort is applied to one end of the rope and the disk of the pulley rotate as the rope moves over it

- If there are several pulleys in a frame work, it is called a block

Types of pulley

Pulleys may be categorized into

- Single fixed pulley

- Single movable pulley

- Block and Tackle system

Pulleys reduce the effort to lift an object by increasing the distance and /or direction over which the effort is applied.

(a) Single fixed Pulley

A single fixed pulley is as single wheel with concave grooves fixed to a support as shown in the figure above. A rope, chain or cable passes over the groove of the pulley. One end of the rope is attached to the load and the effort is applied at the other end.

If a user pulls down on one end of the rope (Effort), the other end (Load) will raise up an equal distance in the opposite direction

The primary benefit of a single fixed pulley is to change the direction of the effort to move a load to a point (such as the top of a flagpole) that cannot be reached by the user.

Characteristics of a fixed pulley system

- It has one wheel inside the pulley

- The pulley is mounted to strong solid support

- Its mechanical advantage = 1

- Velocity ratio = 1

- It is a first class lever because the fulcrum is between the effort and the load

- Has uniform tension in the rope

Application of single pulley system

- Removing water from a well

- Lifting building material in the site

(b) A single movable Pulley

This is a pulley which moves along with the load attached to it. One end of the rope is tied to a fixed support and passes over the pulley and the other end where effort is applied makes a U-turn to the user as shown below.

Characteristics of single fixed pulley

- Its mechanical advantage = 2, that is the effort required to lift the load is half the size of the load.

- Its velocity ration = 2, that is the effort moves twice the distance moved by the load.

(c) Block and Tackle system

This is a pulley system consisting of both fixed and movable pulleys as shown below

The framework of pulleys is called block and the rope passing over each pulley is called tackle.

Characteristics of block and tackle sysytem

- Mechanical advantage (MA) = n (number of pulleys in the system

- Velocity ration (VR) = n (number of strings supporting the load or number of pulleys in the system)

Application of Block and Tackle

They are commonly used to raise or move load in

- Sailing

- Crane

- Lifts

- breakdown

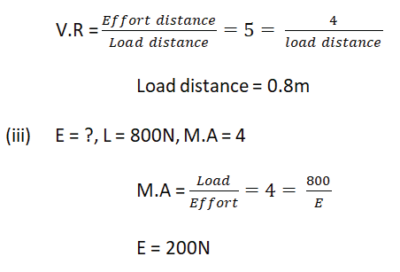

Example 2

A force of 10N is required to raize a load, L, using a smooth (frictionless) and weightless block and tackle system of four pulleys. Calculate:

(i) Load

(ii) M.A

(iii) Effort distance if the load rises by 2m

Solution

Given

E = 10N, M.A = ?, Effort dis. ? Load distance = 2m L ? No of pulleys = 4

(i) in equilibrium

Downward force = upward force

L = 4E = 4 x 10 = 40N

(ii) mechanical advantage

(iii) Neglecting friction,

Work in put = work out put

Work done by effort = work done by load

Effort x effort distance = Load x distance

E x E.d = L x L.d

10 x E.d = 40 x 2

E.d = 8

Therefore, effort distance = 8m

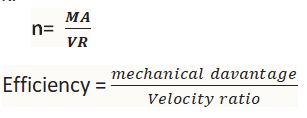

Efficiency of machines

The efficiency of a machine indicates how well its input energy is converted to useful output energy or work.

In an ideal machine (with no friction), the efficiency = 1, also known as 100%.

How can efficiency be increased

- Machines can be made more efficient by reducing friction. This usually is done by adding a lubricant, such as oil or grease, to surfaces that rub together

- For the case of pulleys, by making the string and the block plus the pulleys as light as possible.

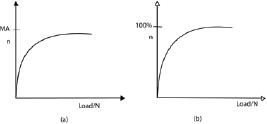

Graphical relationship between M.A and Load

When M.A or n are plotted against load, the following graphs are obtained graph

Explanation of the shape of the graph

In both, a small increase in load cause high increase in M.A and efficiency, n. on further increase on the load, graphs begin to level as M.A and efficiency reach their maximum values and the remain constant.

The efficiency of the pulley system increase with the load because when the load is small, the weight of the lower moving pulley block and friction is significant.

The weight of the lower movable pulley block and friction become negligible to the load as the size of the lad increases.

- For figure (a), the graph levels at the value of M.A. while (b), the graph levels below 100% for imperfect machine and levels at 100% for perfect machines

Example 3

(a) Define the following terms

(i) Mechanical advantage

(ii) Velocity ratio

(b) The diagram in the figure shows a pulley system used to raise the load

(i) What is the velocity ratio of the system

(ii) Find how far the load is raised if the effort moves down by 4m

(iii) Calculate the effort required to raise a load of 800N, if MA = 4

(c) Explain what happen to efficiency of the system in (b) above if the load is much

(i) Less than 800N

(ii) More than 800N

(d) Draw a sketch graph to show how mechanical advantage of the system in (b) varies with the load

(e) Give two practical applications where the pulleys are used.

Solution

(a) (i) mechanical advantage is the ratio of load to effort

(ii) Velocity ration is the ratio of effort distance to load distance

(b) (i) VR = number of pulleys = 5

(ii) Effort distance = 4m, load distance = ?, V.R = 5

(e) they are used in cranes, breakdown, ships, for lifting

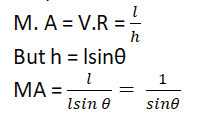

Inclined Plane

This refers to a type of a machine in which a plane is inclined to an angle to the horizontal such that one end is higher than the other by angle, Θ.

- it used to lift heavy load by pulling/pushing it along the sloping surface.

- It is easier to carry the load along the slope than lifting it through the vertical height, h, since the weight of the load acts vertically downwards (and only a component of weight acts along the plane)

- In order to raise the load through a vertical height, h, th effort, E is applied through a longer distance, l, equal to the length of the plane.

Examples of inclined plane include

- Slopping roads

- Stair case

Properties of inclined planes

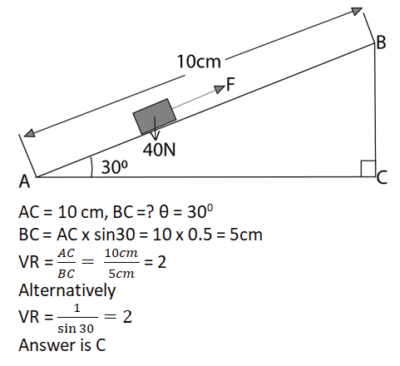

Example 4

A load of 40N is pulled steadily from A to B along inclined plane by a force F as shown in the figure. Find the velocity ratio of the system.

- 0 B. 1.2 C. 2.0 D. 4

Example 5

A wooden plank 3m long is used to raise a load of 1200N through a vertical height of 60 cm. if the frictional force between the load and the plane is 40N. Calculate

(a) The effort required

(b) The mechanical advantage

Solution

Given: L = 1200N, E =? l = 3m, h = 60cm = 0.6m, friction force = 40N

(a) Work input = work out put + useless work done

Work done by effort = work done by load + work by frictional force

Effort x effort distance = Load x load distance + friction force x Effort distance

E X 3 = 1200 x 0.6 + 40 x 3

E = 280N

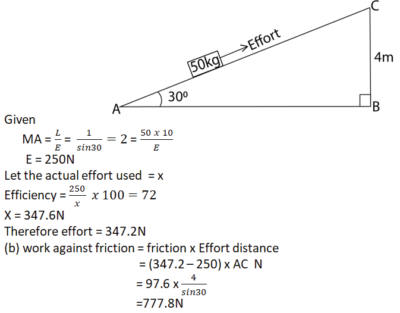

Example 6

A man uses the incline plane to lift a 50 kg load through a vertical height of 4.0m. the inclined the incline plane makes an angle of 300 with the horizontal. If the efficiency of the plane is 72%, calculate

(a) The effort needed to move the load up the inclined plane at a constant velocity

(b) The work done against friction in raising the load through the height of 4.0m (take g = 10Nkg-1)

Solution

The Wedges

The wedge is a kind of simple machine which is an inclined plane having one or two sloping sides. With a wedge, the sloping surface is pushed through the material which is held still.

Examples of wedges are Knife, axe, chisel, needle, nail, razor blade

Uses of wedges include Cutting, pitching

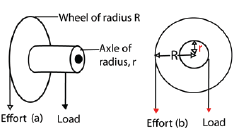

Wheel and axle

A wheel and axle is a type of simple machine made up of a wheel and axles rigidly attached to each other so that they turn together about an axis.

The effort is applied to the larger wheel and the load is raised by string attached to the axle of small diameter as show below:

For one complete turn, the load and effort move through distances equal to the circumference of the wheel and axle respectively.

Characteristic of Wheel and axle

![]()

Uses of wheel and axle

(a) The car steering wheel

(b) Screwdriver

(c) Windlass (used to raise a heavy bucket of water in a well.

Example 7

The figure below shows a wheel and axle system. When an effort of 300N is applied, a load of 900N is raised through a distance of 1.0m.

Calculate

(a) Velocity ratio

(b) The efficiency of the machine

Solution

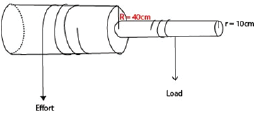

Example 8

A wheel and axle is used to raise a load of 280N by a force of 40N applied to the rim of the wheel. If the radii of the wheel and axle are 70cm and 5cm respectively, calculate the M.A, V.R and the efficiency.

Solution

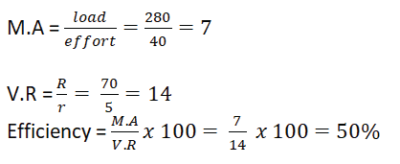

Gears

A gear is a device which consists of a set of toothed wheels. Gears change the direction and speed of rotation. They are similar to wheel and axle. In gear wheel, the effort and the load are applied to the shafts connected to gear.

The velocity ratio of gears depends on which gear wheel is the effort applied.

Torque may be applied to the smaller gear in order to increase the torque and decrease the rate of rotation of the larger gear.

Or

Torque may be applied to the larger gear in order to decrease torque and increase the rate of rotation in the smaller gear.

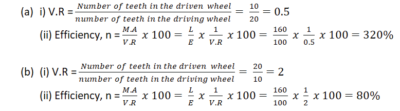

Example 9

Two gear wheels A and B with 20 and 10 teeth respectively lock into each other. They are fastened on axles of equal diameter such that a weight of 100N attached to a string wound around one axle raises a load of 160N attached to a string wound around the other axles.

Calculate

(a) (i) the velocity ratio

(ii) The efficiency of the system when a small gear wheel is the driven gear

(b) (i) the velocity ratio

(ii) The efficiency of the system when a big gear wheel is the driven gear

Solution

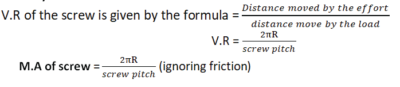

The screw

A screw may be considered as continuous inclined plane wound round a cylindrical threaded rod.

- The distance between two successive threads is called a pitch

- In one revolution, the screw moves forward (or backward) through a distance of equal to one pitch.

- Effort distance equals the circumference of the screw head (2πR)

- Load distance equals the length of the pitch.

- When a screw is combined with lever can be uses as a jack for lifting heavy loads such cars

The velocity ration of screws

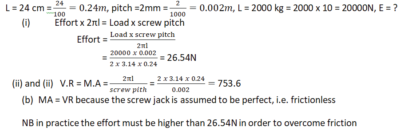

Example 10

(a) In a screw jack the length of the handle is 24cm and the screw pitch is 2mm.if it is used to raise a car of mass 2000kg, calculate

(i)The effort required

(ii) The V.R

(iii) The M.A

(iv) Comment the value of M.A obtained in (a)(iii) above

(Take g= 10ms-2, π = 3.14)

Solution

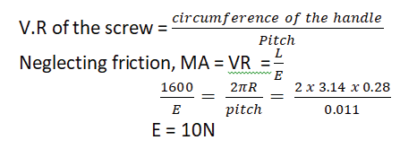

Example 11

A car weighing 1600 kg is lifted with a jackscrew of 11mm pitch. If the handle is 28cm from the screw, find the force applied.

Solution

Factors that may affect the efficiency of agricultural machine and equipment

- Friction: this is the resistance to movement when two surfaces are moving against each other. Some power is lost as the result of friction. Thus when the friction is high the efficiency of the machine is lowered. Fiction may be reduced by lubrication and/or making the surface smooth

- Amount of load: too much load on the machine reduces the efficiency of the machine. Machines should be loaded according to manufacturer’s recommendation

- Conditions of the machine: efficiency is high when a machine is in good mechanical conditions

- Skills of the operator: high efficiency is achieved when the machine is operated according to manufacturer’s recommendation

- Type of the machine: different machine have different inbuilt efficiency

- Topography: machine work well on gentle slope than on steep slopes.

- Level of maintenance and servicing: well-maintained machine retain high efficiency than faulty machines

- Nature of vegetation cover: machine work well with little sparse vegetation than dense thick vegetation

- Soil type: machines work efficiently in light soils than in heavy soils.

- Field conditions such as presence of heavy stones and trees stamps retard the efficiency of a machine.

Work, Energy and Power

(a) Work: is a product of applied and the displacement of the body. Units: joules (J)

Example 12

A body of mass 5 kg is lifted through a distance of 6m. Calculate the work.

Force = mg = 5 x 10 = 50

Work = F x d = 50 x 6 = 30J

(b) Power: is the rate of doing work or the rate of transferring energy

Units: watts

Example 13

A machine lifts a load of 500N through a distance of 10m in 5 seconds. Calculate the average power of the machine

![]()

- Energy: is ability to do work

Types of energy

- Potential energy = mgh where m = mass, g = acceleration due to gravity, h = height above the ground

- Mechanical energy = Kinetic energy + potential energy

- Chemical energy

- Electrical energy

- Nuclear energy

- Light energy

(d) Pressure is force per unit area

Farm mechanization

Agricultural mechanization is the use of machines to perform work on the farm

Farm activities that can be mechanized

- Ploughing, tillage using tractor and ox plough, harrow and rotators used in secondary tillage.

- Planting using tractors or ox plough planter and seeders

- Fertilizer application using fertilizer broadcaster and drills

- Weeding using weeders that are powered by ox plough

- Irrigation using pressurized mechanisms

- Harvesting using tractors mounted harvester or combine harvesters

- Threshing and winnowing using motorized threshing machines

- Milking using milking machines

Benefits of farm mechanization

- Increases agricultural output

- Simplifies work

- Reduces the cost of labor

- Encourage quality production

- Increases speed of doing work and saves time

Limitation of agricultural mechanization in Uganda

- Unavailability of machines

- High maintenance cost of agricultural machines

- Poor land tenure system which discourages long term planning

- Land fragmentation that makes it uneconomical to mechanize.

- Lack of adequate capital to purchase farm machinery.

- Presence of cheap human labor.

- It may lead to over production causing fall of prices

- Requires skilled manpower

- Some operations on farms such as picking coffee are easily mechanized.

- Ragged terrain is not easily mechanized

- Mechanization may expose land to soil erosion

Ways of encouraging mechanization in agriculture in Uganda

- Sensitize farmer about the befits of mechanization

- Encourage group ownership since agricultural machines are expensive

- Provide incentives and subsidies on agricultural equipment

- Train machine operators and mechanics

- Encourage land consolidation to create commercial size pieces of land

- Create market for agricultural produce to encourage farmers to invest on the farm

- Creation of technical engineering workshops at the districts

- Provide agricultural credit and subsidies for purchase of machinery.

Sources of power on the farm

Power is the major driving element in mechanization. It is needed for mobile operations such as transportation of produce and stationary operations such as water pumping.

Common power sources on the farm include human, animals, wind, solar, nuclear and thermal power.

Animal power

This involves the use of animal-like oxen, horses, donkeys, camels and buffaloes

Factors to consider when choosing a draught animal

- Power output: animals with high power output are mostly preferred for use in traction

- Amount of traction: the animal should be able to give fair good traction on soft and slippery ground.

- Availability of animals: availability of a given species of draught animals in the area or nearby areas influences its use on the farm

- Cost of the animal: to minimize the cost of production, farmers may use animals that cost less.

- Level of care: draft animals requiring less specialized and cheaper care are preferred for use on a farm

- Adaptability to local conditions: draught animals are should be well adapted to local conditions.

- Resistance to pest and diseases: draught animals should be resistant to pests and diseases.

- Temperament: cool temperament is highly recommended

- Ability to learn: the animals to choose for draft should be able to learn faster.

Advantages of using draught animals

- They are economical on small scattered plots

- They are cheap to buy and use, does not require fuel

- Draught powered technology requires little skill

- Draught animals provide manure and meat as well

- They deliver higher power compared to man

- No pollution

- Oxen do not depreciate like tractors.

- Have low maintenance costs.

- Create employment opportunities.

Factors limiting the use of draught power in Uganda

- Unavailability of draught animals

- Conservativeness of some farmers to adopt to draught technology

- Availability of alternative sources of power like human labor.

- Lack of capital to purchase draught animals

- Pests and disease

- Lack of skills to use draught animals on the farm

- Poor climate leading to lack of feeds to draught animals

- Presence of heavy soils in most parts of the country.

- Presence of poor topography characterized by steep slopes and ragged terrain

- Thick and tall vegetation that interfere with animal’s work

- Expensive veterinary services

- Unsupportive government policy such high taxation on ox-drawn equipment.

Factors affecting animal power out

- Animal health

- Animal breed

- Workload

- Level of training

- Yoke used for hitching

- Environmental conditions: harsh environmental conditions such hot weather may reduce the amount of power output.

Preparing an ox for a day’s work in the field

- Give the oxen enough water

- Feed the animals so that it does not eat crops

- Yoke the animals properly

- Hold the animals for a while in the dressing room to allow them to settle and calm down

- Cheek the feet of the animals and ensure that the hooves are sound and if necessary pair them

- Fix a muzzle on their mouth to prevent animals from browsing crops.

- Ensure that the implements e.g. a plough is in proper order by sharpening the share and tightening all loose nuts and bolts.

Care given to draught to draught animal on the farm

- Provide good housing to protect the animal from bad weather.

- Timely treatment of animals.

- Control parasites

- Avoid over working the animals

- Provide good nutrition

- Carry out regular foot pairing

- Work the animal during good weather

- During off season the animals should be made to pull carts to ensure that they do not forget

Factors that contributed to the success of oxen-cultivation in Northern and Eastern Uganda

- Availability of hardy draught animals and necessary equipment

- Availability of skilled man power in use of oxen cultivation

- Long experience in use of oxen cultivation

- Good climate

- Presence of light soils that can easily be worked with oxen

- Presence of pests and disease resistant animals

- Availability of land for farming and grazing

- Short and light vegetation

- Relatively flat land that is easy to plough

- Presence of veterinary services

Wind power

It is provided by wind and can be used in doing work such as pumping water, winnowing, and generating electricity

Advantages of wind power

- It is free

- Does not pollute environment

- It is renewable

- Clean

Disadvantages of wind power

- Has initial cost of purchasing and installing wind mill.

- Wind is unreliable/unpredictable

- Wind cannot be controlled

Human power/hand power

It is power provided by human being

Advantages of human power

- Has low initial cost

- Can perform work independently

- It is flexible

- Require low supervision

- Does not pollute the environment

- Readily available

Advantages of human power

- Slow in operation

- Efficiency decrease with number of hours

- Efficiency affected healthy and maturity

- Requires a lot of motivation

Farm tools and equipment

Role of Implements in Farming

Agricultural implements are tools and equipment used to increase productivity and efficiency. These are implements that are used to simplify work such as cultivation, planting, harvesting etc.

Factors considered when choosing a farm tool, machinery and equipment

- Adaptability: farmers prefer implement that can work under the local conditions.

- Availability of implement: farmers select an implement from those available and those with available spare parts.

- Cost of purchase and maintenance: farm equipment should be cheap to buy and maintain.

- Durability: farmers prefer durable equipment

- Number of uses: farmers prefer a versatile machine that performs a number of tasks.

- Size of the farm: big farms require big machines

- Presence of source of power: some farm machines such as milking machines require electricity.

- Presence and level of skilled manpower: some machines require skilled manpower for example use of a tractor.

- Topography: for instance ragged terrain does not favor use of a tractor.

- Level of production: high level production requires large machines

- Availability of capital to purchase the equipment.

- Efficiency of the machine.

General care and maintenance of farm tools and equipment

Reasons to Maintain Agricultural Implements

- Avoid downtime: When an agricultural implement breaks down, it can put a serious dent in your productivity. By taking the time to perform regular maintenance, you can head off most problems before they have a chance to occur.

- Improved Performance: Over time, even the best-maintained equipment will start to show signs of wear and tear. By keeping your implements in good condition, you can ensure they continue operating at peak efficiency.

- Reduce Costs: The cost of repairing or replacing an implement can be high. Maintaining your equipment can minimize the need for costly repairs or replacements.

- Prolong the life: Properly maintained equipment will last longer than neglected equipment. This means less money spent on new equipment over time and fewer disruptions to your operation.

- Safety: Agricultural equipment can be dangerous if not properly maintained. With maintenance on your daily schedule, you can help prevent accidents and injuries.

Maintenance tips for farm implements/equipment

Follow these tips to prolong the lifespan of your agricultural implements.

- Store your implements in a dry, well-ventilated area when not in use. This will help prevent rust and corrosion.

- Clean your implements to remove any dirt or debris that could damage the equipment.

- Inspect your implements regularly for any signs of wear and tear.

- Use only high-quality parts and lubricants on your equipment.

- Avoid excessive force, pressure or impact whenever possible.

- Buy agricultural implements of good quality

- Tighten nuts and bolts of a tool

- Use each tool for the designated purpose

Selected farm equipment

(a) Yoke

A yoke is a wooden beam sometimes used between a pair of oxen or other animals to enable them to pull together on a load when working in pairs, as oxen usually do; some yokes are fitted to individual animals.

Desirable qualities of a yoke to us on the oxen

- Should be strong to avoid breakage during operations

- Should be durable

- Should be light to remove excess weight from the animals

- Should be easily/locally available

- Should be smooth to prevent bruising animals

(b) Ox – Mould board plough (0x-drawn)

Parts of ox mould board plough

- Main beam: holds other parts of the plough

- Mould board: inverts the furrow slices and covers the vegetative materials

- Land side: presses against the furrow wall to separate furrow slices from unploughed land and make the plough stable during Ploughing.

- Land wheel (depth wheel): helps to regulate the depth of Ploughing and enable the operator the gauge a furrow slice within a reasonable distance from the previous furrow line.

- Depth rod: used to adjust width and depth of operation

- Hake: provides attachment on the beam for fixing the parts of the plough which are adjusted before and during Ploughing.

- Link: links the plough onto the chain pulled by the oxen.

- Handle braces: stabilize the plough.

Maintenance practices of the ox-mould board plough

- Regular checking of the conditions of the share; it should be re-sharpened if blunt

- Regularly tight the bolts and nuts

- Replace worn out heel of the land slide

- Clean the plough regularly

- Lubricate the movable parts

- Paint parts to prevent rusting

- Store in cool dry places

Advantages of using ox-mould board plough the farm

- Mouldboard plough produces much uniform seedbed. It ploughs at uniform depth and produces uniform furrows.

- It gives a complete inversion of the furrow slices to completely burry and kill surface vegetation

- The furrow slices are well crushed to give a fine soil tilth favorable for germination of seed.

- It leaves the soil surface relatively smooth since the furrows have shallow depressions and there are no uncultivated strips of land between the furrows.

- It relatively light that it requires less power

- It is cheap

Disadvantages of animal drawn equipment

- They do less work compared to tractors

- Cannot cope up with heavy work; only operate shallow cultivation

- Require land for grazing

- Pulverization of soil encourage soil erosion

- Easily damaged and incur costs to repair

- For animals that work in pair when one animal is sick the other does not work.

- Animals easily tire up when hot or very cold.

Measures to ensure good performance of ox plough

- Pairing of draught animals to increase traction

- Use of light yoke when harnessing the animals

- Feed animals properly

- Treat animals diseases

- Proper hitching of plough on the yoke. Make sure the yoke is fitted properly and the chain length is proper for the team.

- Using the right type of share for the right soil conditions

- Sharpening the share properly before using it on the plough

- Using the right moldboards for the required field condition. Use the digger /stable type for higher pulverization and general for moderate pulverizations.

- Check and tighten loose nuts and bolts

- Clear the field of tall vegetation, and tree first.

- Plough during cool hours of the day.

- Driving oxen at a constant speed

- Ploughing the soil containing moderate moisture.

- Setting the depth wheel correctly to ensure correct Ploughing depths.

- Allow some break intervals during Ploughing to allow oxen to rest.

Tractor mould board plough

Functions of parts of tractor mould board plough are similar to those ox mould board plough

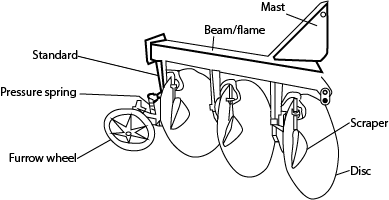

Disc plough

A disc plough is tillage implement drawn by a tractor to cultivate the soil

Functions of parts of disc plough

- Beam: support the whole implement and provides attachment for all parts of the plough.

- Disc: cut, turn and invert furrow slices

- Disc hangers: support the discs and provide room for disc bearing.

- Bearing: facilitate rotation of discs

- Scrappers: clean the discs

- Furrow wheel: balances the plough in steady conditions during Ploughing.

- Mast: mount the plough to the tractor.

Function differences between disc ploughs and mould board ploughs

| Disc plough | Mould board plough |

| Disc plough can roll over obstacle | It glides as long as it plough |

| It requires less power to pull | It requires more power to pull |

| Has poor inversion of furrow slices | Has good inversion of furrow |

| Produces rough seed bed which requires secondary cultivation | Produces relatively smooth seed bed which do not require |

| Can be used to plough in areas with a lot of trash | Cannot be used to plough in area with a lot of trash |

| The rolling action prevents it getting stuck and breaking | Plough gets stuck and can break easily |

| Requires less tractor power to pull the implement | Requires more tractor power to pull implement |

Safety rules when operating a tractor

- Do not get on or off a tractor when it is moving

- Do not clean or grease when a tractor is in motion

- Do not allow other persons to ride on the tractor during operation

- Do not remove or fit the belt to the pulley when the pulley is in operation

- Avoid removing the radiator cap when water is still very hot

- Do not run the engine when the oil gauge does not show any reading

- Never use a clutch pedal as a foot rest

- Do not refuel a tractor when the engine is running

- Do not operate a tractor with faulty tyres, brakes and clutch.

- Do not check level of oil when the engine is running

- Employ skilled drivers

- Do not drive the tractors when drunk with alcohol

- Ensure that the bolts and nuts are tight

- Never drive a tractor near a ditch

- Keep the tractor in well maintained conditions.

Factors that influence the choice of implement used for cultivation

- Soil condition: dry/hard soil require heavy implements like a disc plough while loose soil require light implements like hand hoe and ox plough

- Type of soil: sand soil is light and can easily be cultivated with hand hoe and ox plough while clay soil is heavy and requires disc plough.

- Topography: in hilly areas tractor drawn implements may not be used while hand hoe is ok.

- Nature of vegetation: ox plough is used in areas of short light vegetation

- Availability of capital to purchase a desired implement

- Availability of skilled labor to work with an implement

- Size of land: tractor drawn implements are cheaply used on a large piece of land

- Preference of a farmer

- Depth of cultivation: sub-soilers are required for deep cultivation

Mechanical planter

Components of mechanical planter

- The seed hopper is where seeds are placed

- Seed metering device regulates number of seed planted at a time

- Seed tube delivers the seed from hopper into the planting hole

- Seeds covering device covers planted seed with soil

- Frame provides a base onto which all the components are fitted either directly or indirectly.

- Transport wheels allow the machine to be moved easily

- Depth regulating lever lowers or raises the furrow opener

- Boot joins the furrow opener to the seed tube.

- Drive mechanism transmits power from transport wheel to the seed delivery system.

- Agitator stirs and keeps the seed flowing freely

Advantages of using mechanical planter

- Plants faster and saves time

- Even placement of seeds

- Reduced seed wastage

- Used in fertilizer application

Mechanical faults and solutions to mechanical faults to a mechanical planter

- Seed Depth Variation: If seeds are planted at inconsistent depths, it affects germination. Calibrate the planter to ensure uniform seed placement.

- Double Planting: When two seeds end up in the same spot, it wastes resources. Adjust seed spacing and monitor seed flow.

- Seed Spacing Errors: Uneven spacing leads to uneven crop growth. Regularly check and adjust seed meters and spacing mechanisms.

- Fertilizer Distribution: Ensure even fertilizer application. Check tubes, nozzles, and distribution systems for clogs or malfunctions.

- Worn Coulter Blades: Dull or damaged coulter blades affect cutting and seed placement. Replace worn blades promptly.

- Metering Unit Issues: Faulty seed meters can cause over- or under-seeding. Clean and calibrate meters regularly.

Sprayer

Parts of sprayer

- Nozzle: breaks the spray liquid into droplets for application to the targeted surface.

- Lance: is a tubular frame to which the nozzle is attached.

- Lance holder: provides attachment to the lance

- Trigger valve: regulates the release of chemicals from the nozzle.

- Delivery hose: delivers the spray chemical to the valve and nozzle.

- The pump and pumping lever: builds pressure in the tank.

- Tank: stores the spray liquid.

- Belt: enable the operator to carry the sprayer on the back

- Cap: covers the tank

- Filter: prevents foreign materials from entering the tank.

Steps followed when using a knapsack sprayer

- Prepare the liquid in a separate container following the manufacturer’s instruction.

- Open the cap and pour it in the tank through a filter.

- Close the cap.

- Carry the sprayer to the back.

- Prime the sprayer by pumping the handle about 10 to 15 times.

- Point the nozzle onto the target area and pull the trigger to spray the liquid.

Maintenance practices on sprayer

- Drain the tank of the sprayer before and after use

- Fill the sprayer with water overnight if it is to be used the following day

- Wash both internal and external part of the sprayer when changing to another chemical

- Was the sprayer at the end of the spraying season with soda (0.5kg of soda in 50 liters of water)

- Remove and clean all the nozzles

- Inspect valves for wear and replace in time

- Keep stock of all spares for replacement

Farm buildings and structures

These are construction made on a farm for various functions. They include

- Buildings include stores, offices and animal houses

- Water storage structures such as dams, boreholes, tanks and reservoirs.

- Fences include barbed wires, plain wire, woven fence, trench fence and live fence.

- Animal handling structures such as spray races, dips, crushes

Fence

It is an enclosure that restricts movement of animals and/or people.

Importance of a farm fence

- Restricts movement of animals and people

- Protects the farm from intruders and theft

- Acts a boundary against land disputes.

- Divides a grazing land into paddocks to ensure controlled grazing and breeding

- Protects crops from animals

- Control spread of diseases

Factors that determine the type of fence used

- Farmer’s preference

- Available capital

- Type/size of animal to be restricted.

- Skill required

- Topography for instance

Barbed wire fence:

Here barbed wires are hanged on posts to control movement of animals.

Components of a barbed wire fence

(i) Posts are of four types made of wood, metal or concrete

Strainers (King post)

- They are used to make corners

- They are used to make farm gate

- They keep the train of wire

Standard (ordinary posts)

- They hold, strain and support wire

Droppers

- Prevent wires from sagging

- Maintain spaces between wires

Struts

- They give support to the strainers in corner

- They brace strainer at the gate.

Barbed wire

- Contain barbs at interval that restrain movement of animals. The length of barbed wire required = perimeter x number of strands

Qualities of good barbed wire

- Should have high steel quality to ensure uniform tension to prevent sagging.

- Should have two strands for strength.

- Should not rust easily

The procedure to be followed when constructing a barbed wire fence

- Identify the area to be fenced

- Clear vegetation/bush in the space where the fence line will pass

- Use a string to make the line straight

- Use pegs to set the position of the posts in a straight line (4.6m apart)

- Determine the number of corners and gates since this will give the number of strainers and standard posts required.

- Set the corner and gate posts

- Dig holes about 2 feet deep for standard posts and 3 feet deep for strainer just enough to take the size of the post.

- Fit the posts and struts into the holes

- Fix struts on the strainer at the corner and gate

- Pour concrete or mortar and ram

- Nail struts to the corner and gate posts

- Stretch and staple the first stand of the barbed wire starting from the lower strand to the second upwards

- Fix in droppers where necessary

- Fix gate

Ways of maintaining barbed wire fence

- Replace broken wire

- Treat the posts regularly which recommended preservatives

- Replace decayed posts

- Tighten loose wire with new staples

- Put dropper in between the wires to prevent sagging

- Replace broken gate

Farm Buildings

Architectural drawing

This is a technical illustration of a building or building project.

Types of architectural drawings used in technical work

- Pictorial drawings: drawing an object as it actually appears to the eye. It is also called perspective drawing. This is used by architects in showing the detail of the structure. This drawing shows the building just as a photograph or sketch taken from the same point. But as it cannot be measured, the drawing is of no value to direct building.

- Working drawing: gives information (dimensions and shape) for complete construction of building represented.

- Topographic drawing are drawing of maps and landscape showing the method of representing land and water features and is the kind of drawing used in construction with relation to surveying.

A building plan

It is a drawing showing the location, arrangement and fitting out of buildings and estimates of quantities of material

Advantages of building plan

- Helps in estimating of amount and cost materials to use.

- Guides the builders on the quality of materials to use

- Helps in planned positioning of buildings and rooms

- Helps to locate the underground electric cables and water pipes

- Helps in setting up of the whole farm lay out for easy access of farm and buildings

- Saves time in construction since plan is drawn in advance.

Disadvantage of building plan

- Require skilled interpretation

- Expensive to obtain

- Require skill to draw

- Offer no flexibility in modification

The factors to consider when selecting a site for construction of farm buildings

- Topography: the site should be gentle sloping, free from flooding and erosion

- Wind direction: building for human and animals should be sited on the leeward side of wind. Too much wind can damage buildings and make animals to chill.

- Soil type: the soil should be stable to prevent building from collapsing

- Accessibility: the site should be easily accessible

- Security: the site should be protected from theft and vandalism

- Water supply: the farm site should be able to access water

- A farm site should access electricity

- Future expansion: there should be room for expansion

- Government regulation: farm site location should obey government regulation

- Relationship between enterprises: building for related enterprises should be located close to one another.

- Panoramic view: a homestead and farm house should be located in such a way that the farm can easily be monitored.

- Farmers preference

Factors that should be considered when choosing materials for construction on a farm

- Cost of construction material, cheaper materials are preferred.

- The durability; durable materials are preferred

- Technology needed

- Capital to purchase building materials and pay labour.

- Farmers preference of the material

- The strength of the materials/ability to resist stress and strain

- The ease to work with the materials e.g. painting, vanishing, oiling

- The type/nature of the material e.g. plastic, wood, metal etc.

Possible causes of weakness in farm building

- Poor soil that encourage sinking of the foundation

- Too small a foundation offering too little a surface area to handle weight

- Shallow foundation

- Poor mixing of building material

- Insufficient building material

- Poor grade building material

- Use of inexperienced mason and builder who lacks necessary knowledge.

- Poor draughtsman ship with inherent faults that are transmitted to the building.

Qualities of a good building wall

- Should have sufficient height so that people do not knock their heads

- Should be weather resistant

- Should be fire resistant

- Should have good thermal insulation

- Should be strong and stable to support the roof.

- Should resistant to earth quakes.

- Should be upright

Ways of protecting farm building foundations

- Constructing concrete floor to protect the building from termites

- Fitting of termites and rodent safeguards

- Uses of chemicals to protect the floor from termite

- Regular clearing of vegetation near the foundation to keep away rodents

- Installing of damp proof course to protect it from dampness

- Painting to protect it from water.

- Plastering the walls to protect it from water

- Installing the gutters to protect walls from water

- Install a wider eve to protect the walls from rain water

Importance of stores on a farm

- They protect farm machinery from bad weather and theft

- They increase the value of the farm

- They reduce wastage on a farm by storing excess produce

- They increase profitability by storing farm produce until a good price

- Maintain the quality of the produce stored properly

- Allow timely harvesting

The characteristics of a good farm store

- Should well ventilated for proper aeration

- Should be lockable for security

- Should be fire proof.

- Should be protected from pests

- Should have leak free roof to keep inside dry

- Should have concrete floor to minimize dust

- Should have enough light.

Precautions taken to ensure proper storage of farm produce

- Timely harvesting to protect the produce from post harvesting pests.

- Drying produce to recommended moisture content.

- Dressing the seeds before storage to reduce pest attack

- Storing produce 50cm above the floor to avoid dampness

- Installation of vermin and rodent traps in the store

- Regularly disinfect and fumigate the store to prevent them from pest inversion.

- Install firefighting equipment in case of fire outbreak.

- The walls and the floor should be free of crack not to store pests

- Stores should have proper ventilation

Problems faced by farmers in storing farm produce

- Damages from vermin and rodents

- Theft from workers

- Lack modern preservation methods such as freezing.

- Damage from high moisture content

- Price fluctuation

- Inadequate space

- High costs of rating a store

The functional requirements of animals’ house

- Should have strong walls to reduce accidents to animals

- Should have concrete rough floor to reduce accidents of farmers from falling

- Should have a gently sloping floor for easy cleaning and draining.

- Should have a roof that is leak free to keep it dry

- Should have enough feed and water trough

- Should be well ventilated

- Should be spacious to accommodate animals

- Should have a lockable door for security

The functional requirements of a building for processing equipment

- It should be water proof to keep it dry and prevent damaging machines

- Should be well ventilated to facilitate aeration for easy cooling of machine

- Should have noise and temperature regulator

- It should be fitted with a fire extinguisher to safeguard it in case of fire outbreak.

- It should be spacious to accommodate the machinery and operator

- Should be strong enough to resist vibrations caused by the machine

- Should have stable power supply to run the machines

- Should have emergency exist in case of accident

- It should be easily accessible for transportation of produce

Concrete

Concrete is a composite material composed of aggregate bonded together with fluid cement that cures to a solid over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material.

The recommended proportions of cement : sand : gravel is 1: 1: 3 or 4 respectively by volume

Factors that affect the strength of concrete

- The proportion and type of cement in concrete

- The quality and proportion of sand

- Proportional of water

- Method of mixing

- The care during curing such as wetting of concrete and covering to protect it from effect of fast drying

- Contamination lowers strength of concrete

Advantages of using concrete as a construction material on a farm

- Good insulator that it reduces loss of heat from a building

- It is non-flammable

- Strong

- Durable

- Concrete is easy to mould

- It cheap

- Easy to clean

Disadvantage of using concrete as construction material on the farm

- Concrete is not well reinforced is low in tensile strength

- It is bulky

- It is expensive

- Requires time to cure

- Requires skill to use

- It is degraded by chemical such as acids

- It is cold

Seasoning timber

This a process of reducing the moisture content of timber to make it suitable for various purposes. The following are the different method of seasoning of timber

- Air seasoning, which involves stacking the timber logs in layers in a shed and exposing them to air circulation.

- Kiln-drying, which uses a controlled temperature and humidity in a chamber to dry the timber quickly.

- Chemical treatment, which involves immersing the timber in water mixed with salt or other chemicals to prevent decay and insect attack.

- Heat treatment, which uses high temperature and low oxygen to modify the properties of the timber.

- Hot-air seasoning, which blows hot air over the timber to accelerate the drying process.

Precautions taken when seasoning timber

- Protection of timber from termites, insects and rodents to prevent destruction

- Drying of the timber indoors to allow uniform drying to prevent cracking and shrinkage

- Protection from water and excessive humidity to prevent them from rotting and hasten drying

- Heaped on leveled ground to prevent from wrapping and gap left to allow air circulation.

- Preservation of handling equipment to prevent rotting

Advantages of using wood to make farm structures

- It is relatively cheap

- Durable

- Easily worked with simple tools

- Less labour is required to work with wood

Disadvantages of using wood to make farm structures

- Easily catch fire

- Require treatment to last

- Low strength

- Easily affected by weather

The hot and cold method of treating timber on the farm

- Timber of desired is placed in a drum containing a suitable preservative. The drum is then fired until the preservatives is about to boil for one to two hours and then allowed to cool.

- During heating air in the wood cells and conducting tubes expand and of the air is expelled from the cells and conducting tubes

- As the preservatives cools down, the air in the wood cells and conducting tubes contract creating a vacuum inside the cells and tubes. The vacuum draws the preservatives into the woods.

The qualities of a good wood preservative

- Should be highly poisonous to fungi and insects

- Should be permanent

- Should allow paint to bond on wood

- Should be readily available

- Should be cheap

- Should be non-poisonous

- Should not produce offensive odor

- Should be easy to apply/use

- Ensure adequate water in a radiator.

Drawings of some building equipment

(a) Hacksaw for cutting metal pipes

(b) Bow saw for cutting wood

Please find free downloadable notes, exams and marking guides of agriculture, biology, chemistry etc. on digitalteachers.co.ug website

Dr. Bbosa Science

Good info. Lucky me I discovered your website by chance (stumbleupon).

I have book-marked it for later!

you are in reality a good webmaster. The site loading pace is incredible. It seems that you are doing any distinctive trick. Furthermore, The contents are masterpiece. you have performed a great task on this topic!

Thanks a bunch for the insightful articles on your websiteI’ve submitted my email for subscription but haven’t received the confirmation email

I’m eagerly awaiting your next piece. Office Products

You have a way of making things come to life. Indian Cricket

Explore the competitive MBBS Cutoff Of Government Medical Colleges in Uttar Pradesh for better planning.

Explore the academic standards for government medical schools at MBBS Cutoff Of Government Medical Colleges in Karnataka.

Win exciting rewards and enjoy seamless gaming on Raja Luck.

I appreciate the method you streamlined SEO Link-Building.

Master the art of Link building strategies for much better Google rankings.

Reduce capital expenditure with trusted and economical Server Rental in Gurgaon.